** Fault Message **

SS01: Main Power F0105P1

Tranformer Oil Temperature or Presure Not Ok TE/BE Reduction or VCB trips try to close VCB if open.

Introduction (F0105P1):

The “F0105P1” alert signifies as abnormality in Tranformer Oil Temperature or Pressure, which will directly cause a Reduced TE/BE and VCB will trip. If VCB trips, try to close it again.

⚠️Effects of this fault are:

- Reduction in TE/BE

- GTO pulsing will stop

- Hotel load will off

- VCB will trip

💡Lamp Indication (F0105P1)

LSFI will start blinking & BPFA will glow.

❌Effect

Possibility of Reduced TE/BE, GTO pulsing will stop. Hotel load will off and VCB will trip.

🛠️Action to be taken by Loco Pilot

- “If TE is still available”, then try to clear the block section by Traction.

- “If VCB trips”:

- Immediately Bring the throttle to “0” position then Acknowledge fault by pressing “BPFA” button.

- After that Try to Close “VCB” and try to clear the block section by coasting.

- “If VCB trips”:

- ✅Check Transformer Oil Pump (TFP):

- Manually feel the “inlet/outlet pipes” of under the frame for vibrations/warmth. which indicate the is working.

- ✅Check MCB’s in cubicles:

- MCB 62.1/1 in HB-1

- MCB 62.1/2 in HB-2

- ❌If found tripped,

- then open VCB and reset MCB once.

- ✅If MPH not working:

- Then Switch OFF and ON MCE.

- Keep loco in idle mode for 10 minutes.

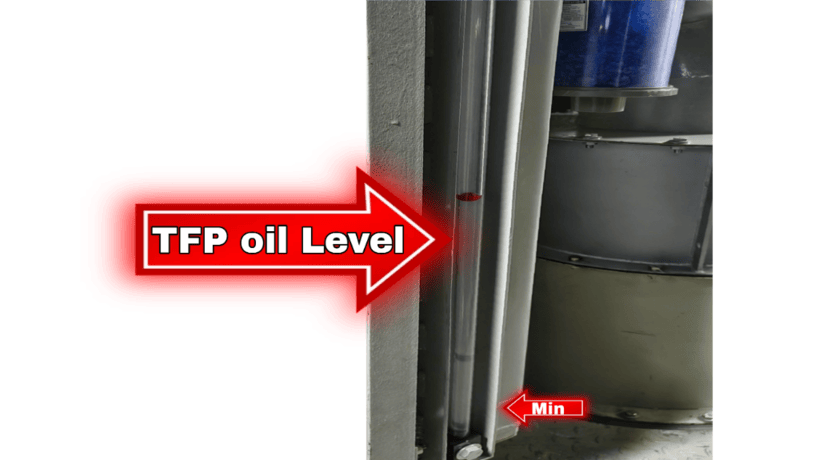

- ✅Ensure Transformer Oil Level:

- Check/ensure the oil level in both the “expansion tanks” of transformer in Machine Room and Oil level should always be “between the Max. & Min Mark”.

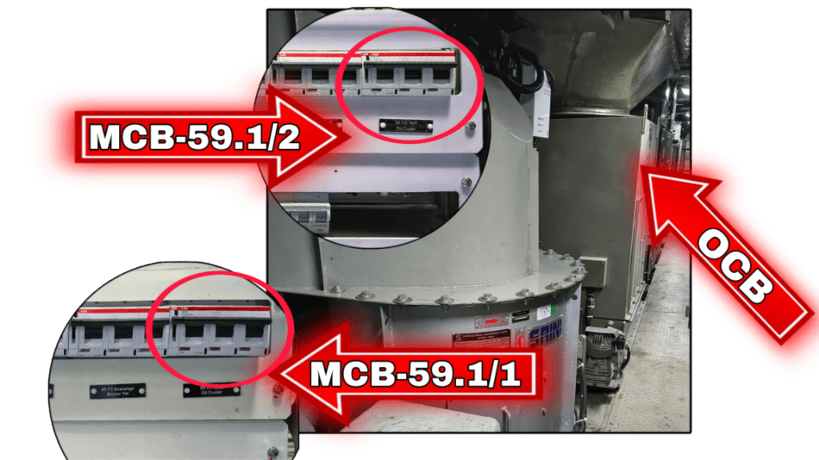

- ✅Check working of (OCB) Oil Cooler Blower in the machine room then

- If OCB is not working then CHECK/ensure that

- MCB 59.1/1 in HB-1

- MCB 59.1/2 in HB-2

- If found tripped:

- Then Open VCB & Reset MCB only once.

- If OCB’s are still not working,

- Then Switch OFF and ON MCE.

- If OCB impeller and its casing got physically damaged:

- Then Isolate Damaged OCB:

- Open MCB 59.1/1 (HB-1) or 59.1/2 (HB-2)

- Open Concerned SR Oil pump MCB 63.1/1 (HB-1) or 63.1/2 (HB-2)

- Open concerned TFP ( Transformer oil pump) MCB 62.1/1 (HB-1) or 62.1/2 (HB-2)

- Then Isolate Damaged OCB:

- ⚠️Operate all above MCB “after opening VCB and switching OFF MCE”.

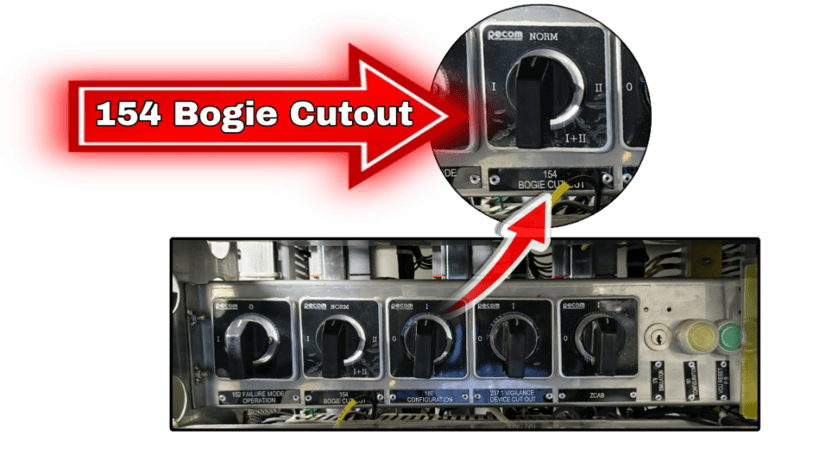

- Then isolate concerned Bogie-by-Bogie using “isolating switch (154)” located in SB-1 .

- then Switch ON MCE ➡️ Raise panto ➡️ close VCB.

- after that Work the train with one Bogie after informing TLC.

** ⚠️Fault Message **

SS01: Main Power F0105P1

Main Power Isolated VCB Inhibited loco is dead

💡Indication Lamp

LSDJ & LSFI will glow

❌Effect

VCB will not close

🛠️Action to be taken by Loco Pilot:

- If the same message repeats and MCB’s are normal:

- Then Bring throttle to “0” position.

- After that Switch OFF and ON MCE once again.

- Then Raise panto ➡️Close VCB ➡️ Resume traction.

- If not successful:

- Check “DDS Message”:

- SLG1:0019 🔜Isolate SR-1

- SLG2:0019 🔜 Isolate SR-2

- if not successful within 20 minutes, ask for relief loco.

Pingback: Fault: F0109P1, AUX. WINDING OVER CURRENT warning msg - LOCO TSD